By Julie Clark McKinney

REV Birmingham Director of Communications

In Birmingham’s early days, our sprawling railroad network was how materials, products and people came and went. A byproduct of that hustle and bustle: Black soot and grime, coating surfaces of nearby historic buildings and warehouses long after railroads cleaned up their environmental act.

So, when a switchyard warehouse is ready for a new life as an industrial office, how does its developer/architect/contractor make sure the most unique original architectural details can shine again?

Yes, this is an oddly specific anecdote – because it’s true. Remember these beautiful rafters we showed you in our Biso Collective photo tour post?

This ceiling is all original to the 1929 warehouse, but it was under a thick layer of soot and it was not known if it could pose a health risk or not. It was so thick the crew wasn’t sure at first whether it could be saved or it should be covered up.

Yes, those are the same rafters. And just in case you’re thinking its the same photo with bad lighting… check out this mid-cleaning shot (cleaned on the left, still sooty on the right, obviously):

Which brings us to a how-the-sausage-is-made kind of story about historic preservation that we thought our fellow building huggers would find interesting.

Murray Building Company, which led the construction project, contracted Alabama Soda Blasting to save the rafters. How did that magic happen?

Soda–blasting, or media-blasting, is like pressure washing but with high-pressure air and dry media, rather than water. The technique can be used to remove dirt, soot, rust, stains, paint, mold and mildew from hard surfaces.

In the case of the wooden rafters at Biso Collective, Alabama Soda Blasting pressurized a spray of baking soda, which acts as a nonabrasive cleansing agent. Baking soda penetrates the coating (paint, soot, dirt, grime, etc.) and expands, removing the unwanted stuff while leaving the wood unharmed.

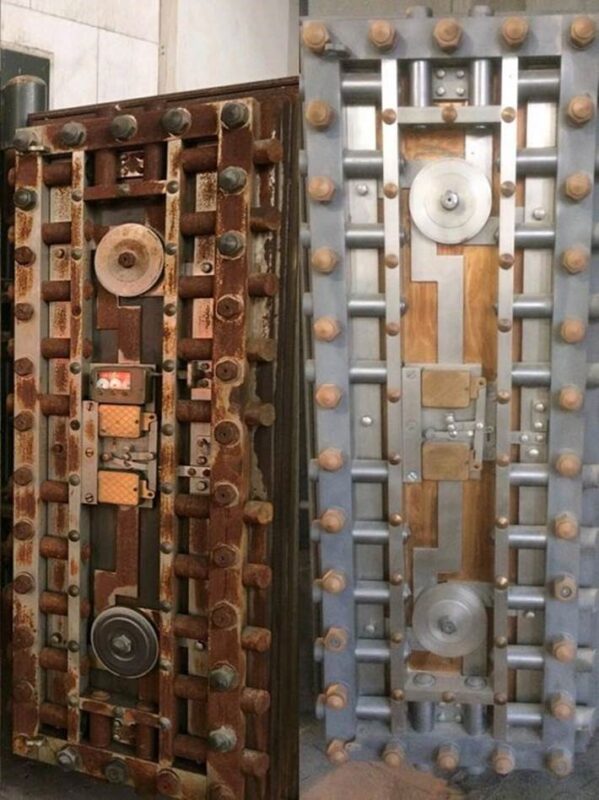

The same company worked at the historic Federal Reserve Building on 5th Avenue North to restore the huge metal bank vault doors, several exposed brick walls and metal-framed windows. They used recycled crushed glass on the metal and baking soda on the brick and window frames.

Depending on what exactly they’re cleaning/restoring, Alabama Soda Blasting might use tiny plastic beads, crushed glass, coal slag, ground corncob or ground walnut shells.

You may have also heard this process called sandblasting, but sand is no longer used in media-blasting because the dust created when using Crystalline Silica has been identified by the EPA as a human lung carcinogen.

Media-blasting can be used to uncover and clean original features like brick walls, concrete floors, metal doors or window frames, and wood. Specialists like Alabama Soda Blasting can help maintain the quality of details that architects layout for historic buildings.

Media-blasting can be used to uncover and clean original features like brick walls, concrete floors, metal doors or window frames, and wood. Specialists like Alabama Soda Blasting can help maintain the quality of details that architects layout for historic buildings.

“We are not trying to figure out how to cover something up,” said Alabama Soda Blasting’s John Burdeshaw. “We’re interested in restoring it to its original glory. We’re not looking for the quickest, easiest or cheapest way. We’re looking to do it correctly and reveal original beauty.”

Burdeshaw says contractors, architects and property owners often end up loving the cleaned, unfinished surfaces and choose to leave them exposed – but media-blasting also gives painters a clean starting surface, which turns a 3-5 year paint job into a 15-20 year, and better-looking, paint job.

John Burdeshaw

Alabama Soda Blasting

- Phone

- Phone 205-365-3856

Related News

-

Why we say yay to two-way streets

Filed Under: Developer, Downtown Birmingham, Filling Vacant Spaces, Front Page, Transportation, Yaysayers

REV Birmingham is a long-time advocate for making the switch to two-way streets downtown, and this is something recommended by planners studying our downtown for years. In fact, the team that developed the 2004 City Center Master Plan recommended many street changes but noted 4th Avenue North conversion should take place “immediately.” We believe this project is a catalytic moment for Birmingham – but you may find yourself wondering why that is.

-

The Key Tool for Urban Revitalization: Downtown BHM's Business Improvement District

Filed Under: Business-Proving, Developer, Downtown Birmingham, Front Page, Get Involved, Potential-Proving, Why BHM

By the time REV took on BID management in 2018, downtown had a new set of needs from its BID. Downtown Birmingham in the ‘90s had a population mainly of 9 to 5 employees. But the downtown of 2018 had a whole new population of residents and visitors throughout the day and night. We had new opportunities to create positive experiences, inviting them into more downtown businesses and public spaces, and to keep them coming back for more.

-

Introducing the six businesses that call Nextec home

Filed Under: Business-Proving, Developer, Downtown Birmingham, Filling Vacant Spaces, Front Page, Historic Preservation, Potential-Proving, Why BHM

On the corner of 3rd Avenue and 16th Street North, you’ll find Nextec, a redevelopment of the 90-year-old, 65,000-square-foot Edwards Motor Company building (also formerly known as the Sticks ‘N’ Stuff building). With experience in historic renovation, developer Michael Mouron, chairman of Capstone Real Estate Investments, began this civic project in 2021 as a space for business startups to continue their work in the Magic City – a function encouraged by REV Birmingham.